- 021-31223500

- info@sheasydrill.com

Electroplated manufacturing at

Fine diamond grit

Sharp and durable

Size:60mm,80mm, 100mm, 160mm, 180mm, 230mm

1.Thanks to the electroplated diamond layer, these blades remove material quickly and efficiently, making them suitable for cutting and grinding hard and abrasive materials such as reinforced concrete, granite and other natural stones.

2.The electroplated diamond layer ensures precise and controlled cutting and grinding, allowing for precise shaping and contouring of the material while minimizing chipping or damage.

3. Electroplated diamond blades last longer than traditional ground blades, resulting in less downtime and cost savings over time due to fewer blade changes.

4.The electroplated diamond layer dissipates heat more efficiently, reducing the risk of blade overheating and minimizing thermal damage to the workpiece.

5.These blades provide a smoother, cleaner finish on the workpiece than traditional ground blades, making them ideal for applications where a high-quality surface finish is important.

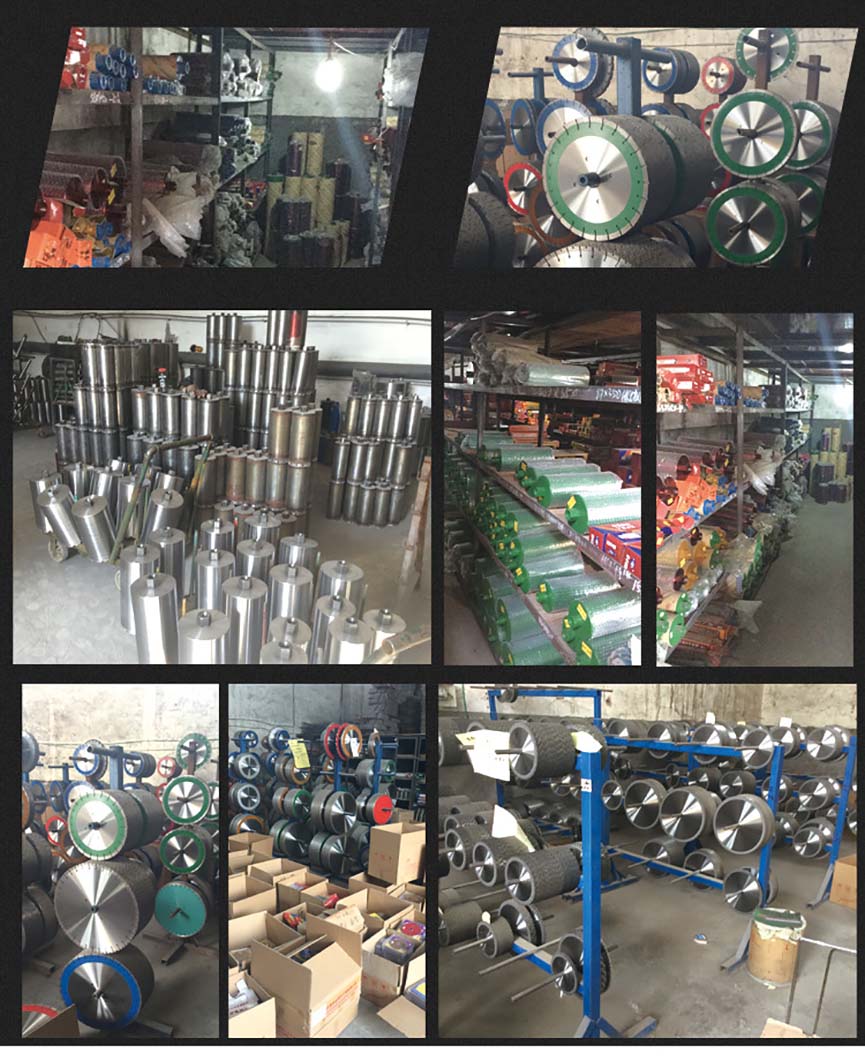

With material applications in mind, Shanghai Easydrill Industrial Co.,Ltd, long a leader in high speed steel, cobalt, and carbide drill bits for metal, features a complete line of drill bits and hole cutting solutions for metal, wood, concrete, masonry,glass and other surfaces. Drilling, hole cutting, reaming, countersinking, tapping, milling, sawing, and deburring are comprehensively covered with Easydrill.

Copyright © 2025 Shanghai Easydrill Industrial Co.,Ltd.