- 021-31223500

- info@sheasydrill.com

Fine diamond grit

Smooth and durable

Vacuum brazed manufacturing art

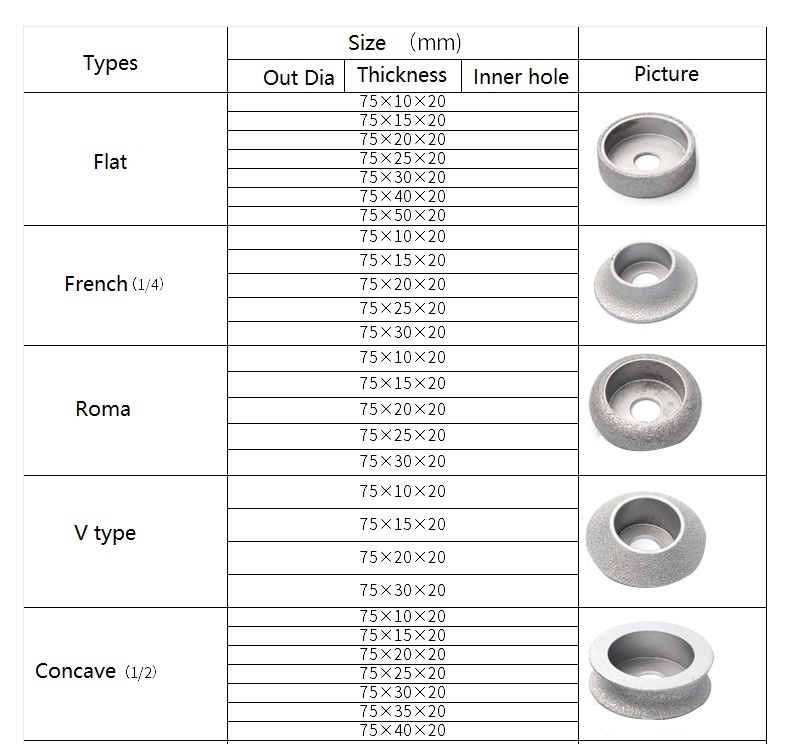

Flat edge

1.These grinding wheels are versatile and can be used to grind and shape a variety of materials such as natural stone, engineered stone, concrete, ceramics, and more.

2.The flat edge design allows for precise grinding and shaping of edges and contours with accuracy and consistency, making it ideal for tasks requiring intricate detail and smooth surfaces.

3.The vacuum brazing process creates a strong bond between the diamond particles and the grinding wheel base material, resulting in a durable and long-lasting grinding tool. This reduces the need for frequent replacement and maintenance.

4.Vacuum-brazed diamond particles provide a powerful cutting action, enabling efficient material removal and shaping even in hard and dense materials.

5.The strong bond between the diamond particles and the grinding wheel helps reduce the risk of chipping or falling off during use, maintaining the integrity of the workpiece and improving safety.

6.The vacuum brazed design effectively dissipates heat during the grinding process, reducing the risk of overheating and extending the service life of the grinding wheel.

7.The special profile and precise distribution of diamond particles on the flat-edged wheel allow for smooth and precise grinding, resulting in a high-quality finish and precise contours.

8.The open construction and efficient debris removal of flat-edge vacuum-brazed diamond grinding wheels help reduce clogs, minimizing downtime during operation.

With material applications in mind, Shanghai Easydrill Industrial Co.,Ltd, long a leader in high speed steel, cobalt, and carbide drill bits for metal, features a complete line of drill bits and hole cutting solutions for metal, wood, concrete, masonry,glass and other surfaces. Drilling, hole cutting, reaming, countersinking, tapping, milling, sawing, and deburring are comprehensively covered with Easydrill.

Copyright © 2025 Shanghai Easydrill Industrial Co.,Ltd.