- 021-31223500

- info@sheasydrill.com

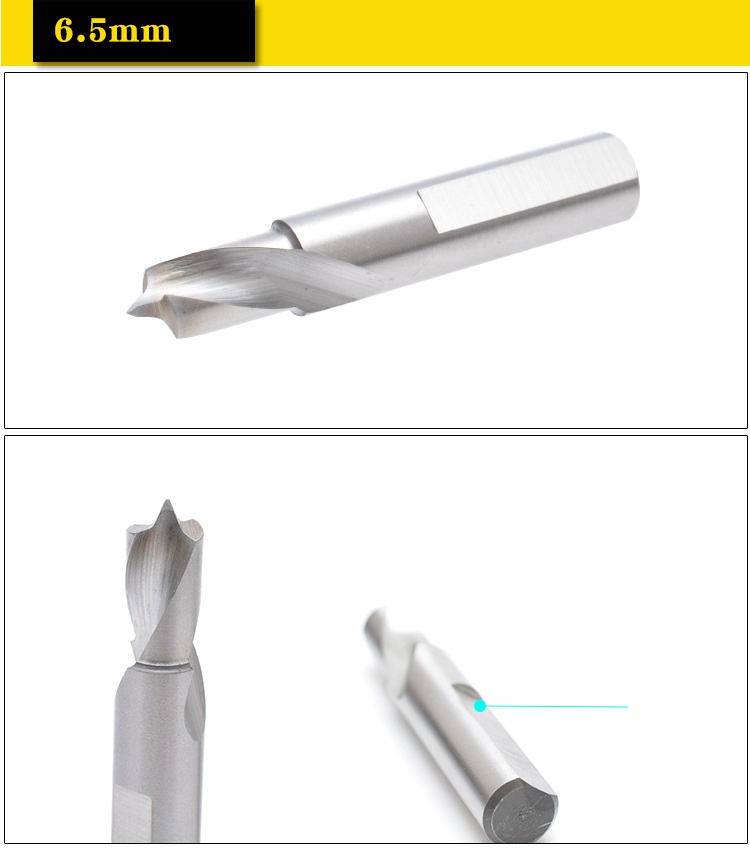

Surface Finish: white,amber,titanium Finish

Manufacturing art:fully ground

Size(mm): 6.0mm-8.0mm

Shank: straight shank

1.Cobalt Structure: High-speed steel (HSS) containing cobalt alloys is often used to increase hardness, heat resistance and durability.

2.Groove Geometry

3.Many spot weld remover drill bits are equipped with a pilot point or centering tip to provide precise and controlled drilling, minimizing the risk of slippage and damage to surrounding material.

4.High Heat Resistance:

1. Precision: It is designed to precisely locate and drill out solder joints without damaging the surrounding metal, ensuring precise, clean removal.

2.DURABILITY: High-speed steel construction provides excellent durability and wear resistance, allowing the drill to withstand the demands of spot weld removal without dulling quickly.

3.Efficient Chip Evacuation: The twisted design and groove geometry are optimized for efficient chip evacuation, preventing clogging and maintaining cutting performance during spot weld removal.

4.Compatibility: Drill bits are typically designed to be compatible with a variety of drilling machines, making them versatile and suitable for different spot welding applications.

5.Versatility: It can be used to remove spot welds from a variety of materials, including automotive body panels, sheet metal and other metal fabrication projects.

6.Reduces heat build-up: The design of the drill helps minimize heat build-up during drilling, extending tool life and reducing the risk of damaging surrounding materials.

These advantages make the HSS Spot Weld Remover Twist Drill a valuable tool for efficient spot weld removal in automotive repair, metal fabrication, and other industrial applications.

With material applications in mind, Shanghai Easydrill Industrial Co.,Ltd, long a leader in high speed steel, cobalt, and carbide drill bits for metal, features a complete line of drill bits and hole cutting solutions for metal, wood, concrete, masonry,glass and other surfaces. Drilling, hole cutting, reaming, countersinking, tapping, milling, sawing, and deburring are comprehensively covered with Easydrill.

Copyright © 2025 Shanghai Easydrill Industrial Co.,Ltd.