- 021-31223500

- info@sheasydrill.com

Vacuum brazed manufacturing art

Fine diamond grit

Sharp and durable

Size:60mm,80mm, 100mm, 160mm, 180mm, 230mm

1.Vacuum brazed diamond saw blades have a high concentration of diamond particles, which are bonded to the steel core through a vacuum brazing process. The result is a durable and long-lasting blade that maintains its cutting or grinding efficiency over time.

2.Vacuum-brazed diamond particles offer high levels of aggressiveness, removing material quickly and efficiently, making the blade suitable for demanding cutting and grinding tasks.

3.Vacuum-brazed diamond layers provide a smoother cutting and grinding action, reducing the chance of chipping or damaging the workpiece, resulting in a clean, precise finish.

4.The vacuum brazing process and the design of these blades effectively dissipates heat, reducing the risk of workpiece overheating and thermal damage.

5.Vacuum brazed diamond saw blades are suitable for both dry and wet cutting applications, providing flexibility and convenience for different working conditions.

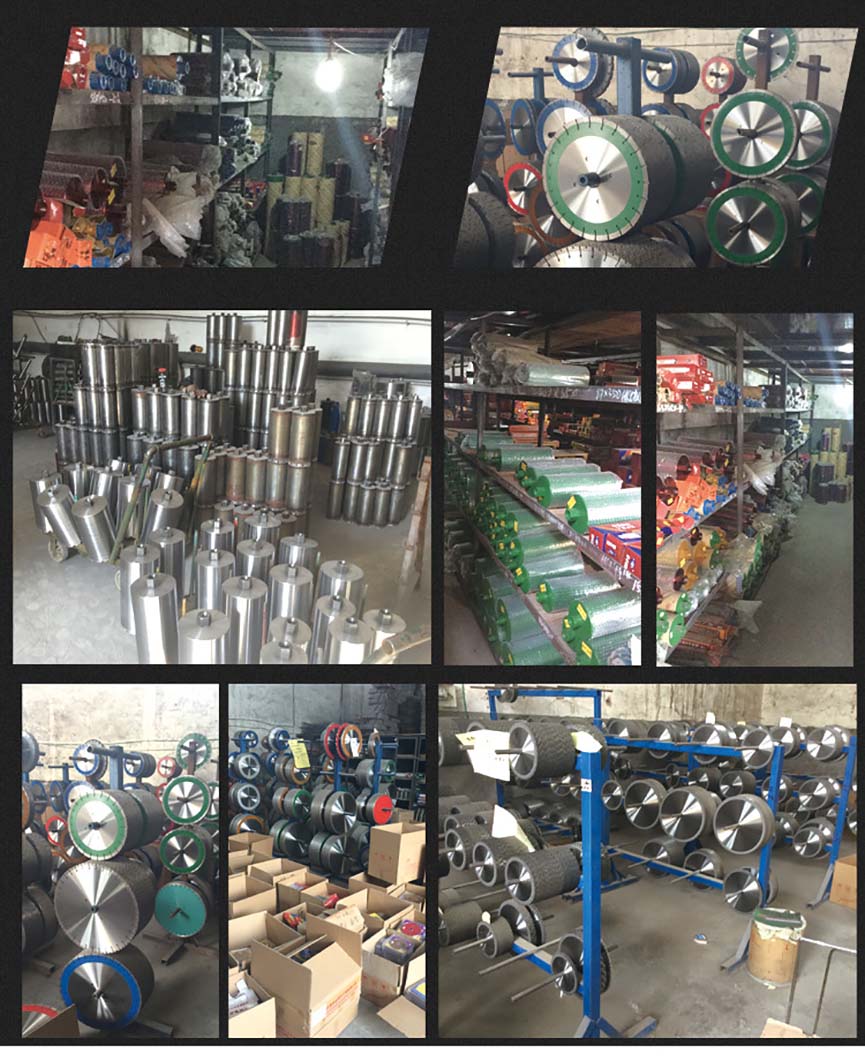

With material applications in mind, Shanghai Easydrill Industrial Co.,Ltd, long a leader in high speed steel, cobalt, and carbide drill bits for metal, features a complete line of drill bits and hole cutting solutions for metal, wood, concrete, masonry,glass and other surfaces. Drilling, hole cutting, reaming, countersinking, tapping, milling, sawing, and deburring are comprehensively covered with Easydrill.

Copyright © 2025 Shanghai Easydrill Industrial Co.,Ltd.