- 021-31223500

- info@sheasydrill.com

Material: HSS

staight shank

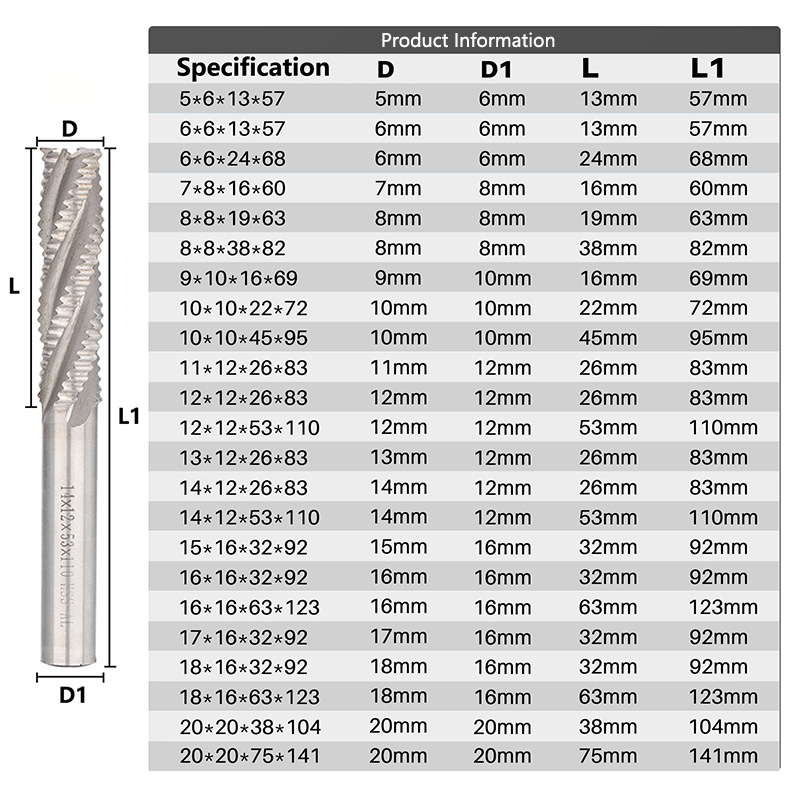

Size(blade dia*blade length*shank dia*overall length*F):

D6*15*D6*60*4F,D8*20*D8*65*4F,D10*25*D10*75*4F,D12*30*D12*80*4F,D14*35*D12*90*4F,D16*40*D16*95*4F,D18*40*D16*105*4F,D20*45*D20*110*4F,D22*45*D20*110*5F,D25*50*D25*120*5F.

Specific end geometry

Durability, versatility, and cost-effectiveness

High-speed steel (HSS) roughing cutters offer a variety of advantages for a variety of milling applications. Some of the key advantages of HSS roughing cutters include:

1. High-speed steel roughing milling cutters are suitable for processing a variety of materials, including steel, stainless steel, cast iron and non-ferrous metals, providing versatility in milling operations.

2. High wear resistance: High-speed steel cutting tools are known for their excellent wear resistance, allowing them to maintain cutting performance for a long time, especially when machining tough or abrasive materials.

3. High-speed steel roughing cutters are generally more cost-effective than solid carbide tools, making them the first choice for applications that don’t require high cutting speeds and feeds.

4. Toughness: High-speed steel cutting tools exhibit toughness and durability, allowing them to withstand interrupted cuts, heavy loads, and impact loads without chipping or breaking.

5. Regrinding ability: High-speed steel rough milling cutters can be regrinded multiple times, extending service life and saving costs in the long term.

6. Suitable for low-speed applications: High-speed steel cutting tools are well suited for low-speed milling operations, making them ideal for applications that do not require high cutting speeds.

7. Flexibility: High-speed steel roughing milling cutters are available in a variety of sizes and configurations to flexibly adapt to various milling requirements and workpiece geometries.

8. Machining of large workpieces: High-speed steel roughing cutters are suitable for machining large workpieces due to their robustness and ability to handle heavy cutting loads.

With material applications in mind, Shanghai Easydrill Industrial Co.,Ltd, long a leader in high speed steel, cobalt, and carbide drill bits for metal, features a complete line of drill bits and hole cutting solutions for metal, wood, concrete, masonry,glass and other surfaces. Drilling, hole cutting, reaming, countersinking, tapping, milling, sawing, and deburring are comprehensively covered with Easydrill.

Copyright © 2025 Shanghai Easydrill Industrial Co.,Ltd.